Air Separation

Air separation is a common process to extract gases from atmospheric air. The main gases extracted are nitrogen and oxygen.

Air separation is a common process to extract gases from atmospheric air. The main gases extracted are nitrogen and oxygen.

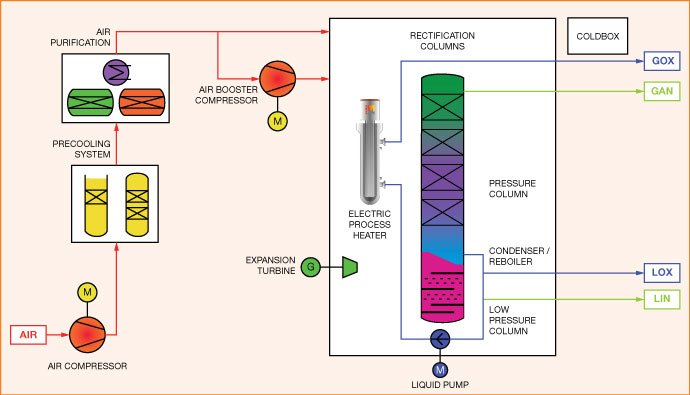

Cryogenic air separation units (ASU) utilise the varying condensing/boiling points to enable separation by distillation at cryogenic temperatures. Liquefying and distilling air provides a process to successfully separate the nitrogen and oxygen.

Modern ASUs utilise a Prepurifier Unit (PPU), which removes moisture, CO2 and most hydrocarbons from the air to prevent ice and dry ice forming later in the process. A PPU is typically made up of a chiller to cool the air to 40 to 55°F, a condensate separator to remove free water and two vessels filled with desiccant and mole sieve material which adsorbs the contaminants while allowing the air to pass through. The desiccant and molecular sieve bed is regenerated by passing heated waste nitrogen to remove accumulated contaminants. Electric heaters are used to heat the waste nitrogen.