High-Temp/Large Delta-T Applications

EXHEAT, with its knowledge gained over the years, uses variable watt densities to achieve different heat transfer in various stages of the heater. This ensures the elements are at the correct temperature and will not exceed the thermal cracking temperature of the media flowing through.

EXHEAT, with its knowledge gained over the years, uses variable watt densities to achieve different heat transfer in various stages of the heater. This ensures the elements are at the correct temperature and will not exceed the thermal cracking temperature of the media flowing through.

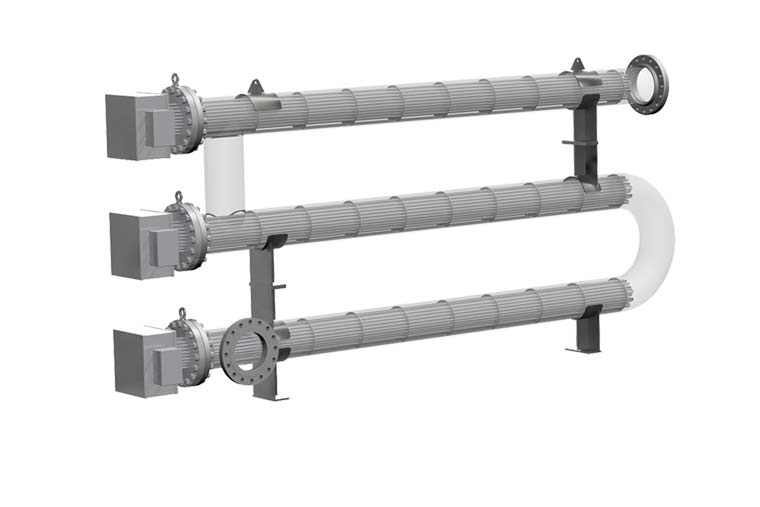

Multiple heaters are connected in a series of vessels for optimal heat transfer and allow for varying heat input across the required load. Our design includes heat shields and insulation discs for terminal box temperature protection and the use of rod-type baffles to meet heat transfer requirements, whilst ensuring a very low pressure drop.

This system can be used for many processes such as:

- Catalyst reduction, hot H2 stripping, oxidation and reactivation

- Continuous catalyst regeneration

- Reactivation burning

- Gas regeneration